Energy Monitoring System : "To Save Electrical Energy, Monitor it" |

Day by day, with increasing cost of electricity and when energy cost is major contribution towards the cost of product or services, it has become essential to reduce cost of electricity consumption to control production or services cost. To reduce it, first step is to monitor the electricity consumption (Kwh) part-wise or group-wise in any machine, plant. Once the individual consumption can be monitored continuously, then it is possible to identify the energy consumption (Kwh) pattern and fix the areas where energy consumption (Kwh) needs attention.

Day by day, with increasing cost of electricity and when energy cost is major contribution towards the cost of product or services, it has become essential to reduce cost of electricity consumption to control production or services cost. To reduce it, first step is to monitor the electricity consumption (Kwh) part-wise or group-wise in any machine, plant. Once the individual consumption can be monitored continuously, then it is possible to identify the energy consumption (Kwh) pattern and fix the areas where energy consumption (Kwh) needs attention.

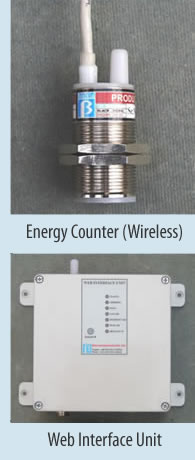

Then it becomes easy to audit and take corrective measures to reduce energy consumption (Kwh). The system for energy monitoring is simply �plug and play� type. It is just integration of standard available Energy meters or Energy transducers, our Energy Counter (Wireless) and Web Interface Unit (Wireless). The Energy meters / Transducer with pulse output are connected to different parts of machine or plant. These pulse outputs are connected to each one of our wireless Energy Counters (wireless). Each Energy Counter (Wireless) records the energy consumption and sends data continuously to Web Interface Unit (Wireless).

The Web Interface Unit collect data originated from all the energy meters / Transducers to create the complete records. The system is available over LAN for continuous monitoring. The system will record the data, create periodic Audit reports in worksheet format, and send reports over email. The system can be deployed practically anywhere, when there is such requirement to monitor energy consumption (Kwh), audit and take corrective steps to control it and finally reduce the energy cost.