Plant Monitoring System (PMS) |

||

In many industries, the production data is collected manually. This involves man-power and reliability of data is always doubtful. Moreover, the manual data collection cannot give timely reports, hence continuous monitoring of machines is not possible to take corrective actions. Our Plant Monitoring system just serves this purpose. It monitors all the machines in real-time, provides necessary data like production, ON time, machine downtime, machine status, order status, operator status, efficiency and batch production.

The Plant Monitoring System is a highly integrated, state of the art, and virtually maintenance free system. It is suitable for automation of manual processes of 'Pulse' and 'Time' data Counting, Recording, Continuous Monitoring and Reporting applications. The Data can be of different parameters like no. of rotation, Production, no. of objects, energy consumption pulses, machine ON time or OFF time, etc.

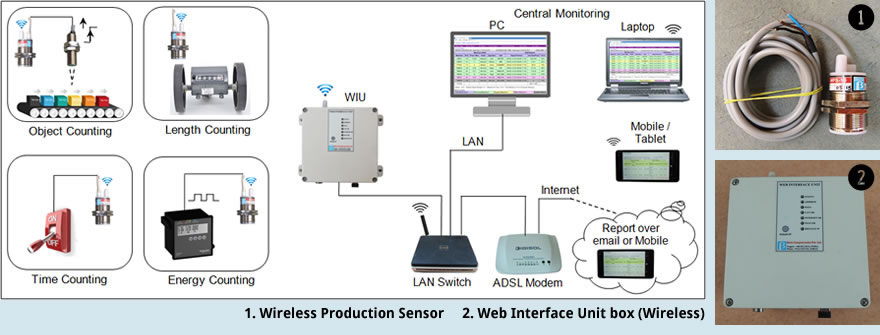

The system consists of Web Interface unit and Wireless Sensors / Counters. The Sensors are installed on different machine and communicate with Web Interface unit wirelessly, through ISM 868 MHz band. The Web Interface Unit can connect to Office or Factory LAN by Ethernet cable. Optionally you can use Ethernet to Wireless router, so that data is also available to Mobile Phone and tablets. The Web Interface unit collects the data from sensors periodically, and presents it to your PC as web pages. Your PC connects to Web Interface unit by a browser like Chrome, Internet Explorer and hence you do not need any special software on PC. The system is fully automatic and no manual interference is required unless you want to change settings.

Features and Advantages

- Simple, Economical and reliable system for automated centralized monitoring of production, machine, energy and utility.

- Wireless production sensor is available in two options: Built in sensing or external input.

- Sensor has pulse or time counter and ON time counter in minutes.

- Continuous monitoring of machines on current page shows number of machines running, stopped, offline and disable.

- "STATUS Report" of all machines 'at a glance' is also available.

- Periodic reports are sent over email automatically and reports are also stored in CSV format.

- Periodic report generation can be every hour, every shift, every day, every month. 32 reports are saved for each category.

- Order and batch monitoring and reporting is provided for managing different orders executed on machines. Order Reports are available to view anytime (also in CSV format).

- Performance analysis is another most useful facility to analyze machine and operator performance for different time periods like hours, shift, day and month. It provides operator wise and machine wise report for selected period. This data will be available for last 32 reports.

- Production Efficiency and Time Efficiency are calculated for all machines.

This system will help to change the way you manage the plant and make it systematic and dependable.